The sun emits light in all directions in space with essentially the same energies in all directions. A candle has a cylindrical wick, so other than the ends, the light is emitted in all directions with uniform energy. An incandescent light bulb with a tungsten filament emits light similar to light from a candle. A gas-discharge light such as a fluorescent tube or a High-Pressure Sodium streetlight also emits light uniformly in all directions. As the light disperses, it follows an inverse square law, become less and less dense as it propagates into space. What makes the light from LEDs any different from any other type of light?

Flat Surface Source

The sun, candle, incandescent, and gas-discharge are all examples of mathematical point sources of light. The shape of the emitter is curved. To be entirely accurate, these emitters may be cylindrical or curly, but the basic concept is that the emitter is curved. Light Emitting Diodes emit visible radiation from a flat surface, not a curved surface. This means that all the light is emitted in the forward direction. This light, however, is not emitted as just half of a sphere. Because the emitter surface is flat, the light rays, which depart the surface at random angles, overlap each other, and create a directed beam of light. This type of flat surface emitter is entirely new for planet earth and is not something that exists in nature.

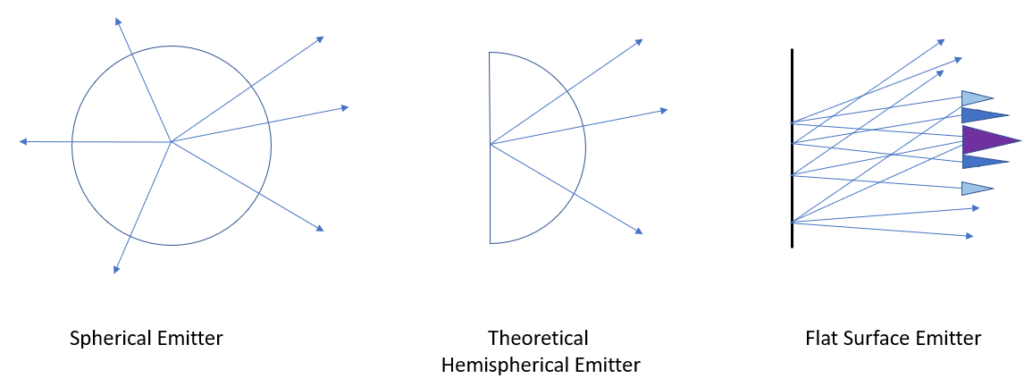

Figure 1 shows a curved surface source on the left. The light rays exit in all spherical directions with the same energies. A flat surface emitter does not emit just half of these rays in one direction, as shown in the middle of Figure 1, because the flat surface causes something else to happen. The right side of Figure 1 shows how the light rays overlap each other due to the flat surface, which creates a non-uniform energy profile, where the middle of the flat surface has very intense light, much more dense than the light at the edges of the flat surface. Light from a flat surface should more accurately be called a light beam.

“Flat light sources produce Lambertian light distributions and only flat light sources do this. This means that luminous intensity and luminance are both non uniform in space for the source and what the viewer sees. ALL of illumination scientific theories are based on point light sources, which means there is spherical uniformity for luminance and luminous intensity regarding the light source and what the viewer sees.” – February, 2022 – Dr. M. Nisa Khan, President IEM Lighting Technologies and Author, Understanding LED Illumination.

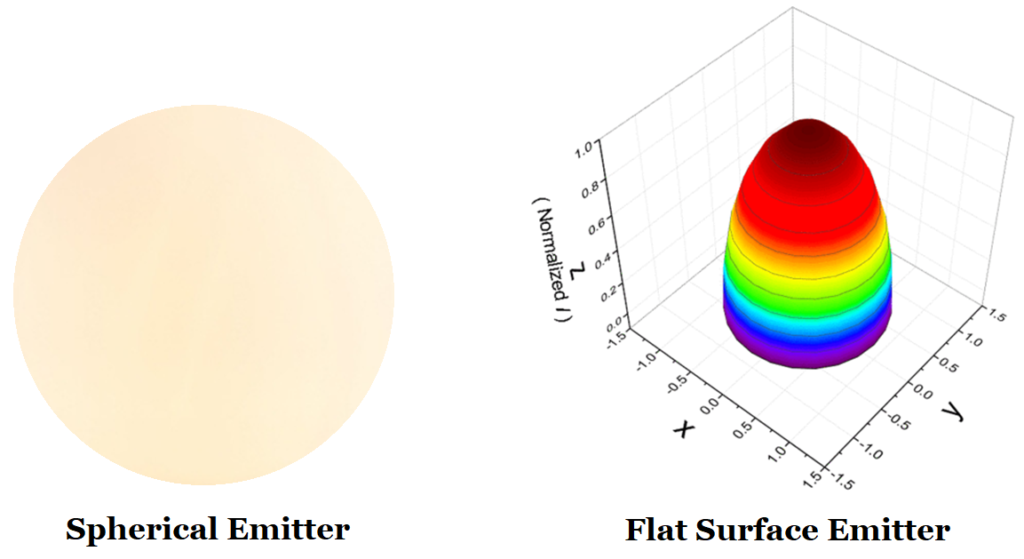

The art and science of illumination for the past 150 years have been predicated on the foundational premise that the light source can be reduced to a single infinitely small mathematical point. For a curved surface source, the light emanates in all spherical directions uniformly, such that taking measurements at any point in space would result in the same readings. This is shown on the left side of Figure 2.

Light Emitting Diodes, however, emit light from a flat surface, meaning that there is no curvature of the surface. The light leaves the chip surface within a given escape angle and because of the flat surface, the light rays intersect. The largest amount of intersection occurs in the middle of the chip and the least amount occurs on the chip edges. The resulting shape of the light from an LED is a spatial energy profile resembling a bullet, as shown on the right side of Figure 2. LEDs are not mathematical point sources, but are mathematical Lambertian sources.

Effects of Using a Flat Surface Source

The history of the science of light is based on light from a mathematical point source. The textbooks explain the properties of light with the assumption that the light energy is uniform in all directions. Our understanding of how light illuminates a room and reflects off a surface to provide our eyes and brain with information about color and shape is based on the premise that the light source is curved. Laws, regulations, and standards were all written with the implicit understanding that the light energy is uniform in all directions.

So what happens when we switch to using a flat surface, where the light energy is not uniform in all directions? What should have happened is that all of the textbooks should have been updated, all the laws, regulations, and standards should have been updated, and all the mathematical formulas and software should have been updated. However, this hasn’t happened. Instead, the engineers, and lighting designers, and policy makers simply continued using the old formulas and old standards and the result is that everything about LED light installations is wrong.

Roadway Lighting

For example, there is an industry group called the Illuminating Engineering Society. The IES publishes a standard called IES RP-8-18 which details how to use light to illuminate a roadway or parking lot. When flat surface LEDs were invented, the IES did not create a new standard for flat surface LED lighting. Instead, the IES wrote that LEDs are point sources3; however, this is not true. Light from a spherical emitter can be modeled as a mathematical point source because the energy is uniform in all directions, but LEDs emit non-uniform energies. We can’t simply call an LED a mathematical point source and ignore that the energy is different depending on the angle. This doesn’t work mathematically and ignoring the fact that the energies are different at every angle produces invalid photometric results.

To correct the problem, the IES needs to create an entirely new standard for roadway lighting for flat surface emitters. In March, 2022, the IES and the US Department of Energy quietly recognized this problem and entered into an agreement to develop metrics and standards for LEDs. While the effort to create metrics and standards for LEDs is welcome news, these standards are coming at least 20 years too late.

Vehicle Headlights

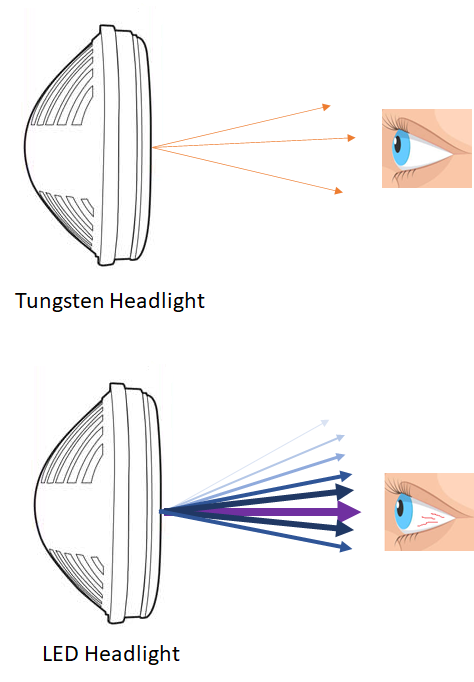

Another example of invalid standards is in relation to vehicle headlights. In the USA, the regulatory agency for motor vehicles is called the National Highway Traffic Safety Administration. NHTSA created a regulation called the Federal Motor Vehicle Safety Standards, and Section 108 details the requirements for vehicle headlights. As FMVSS-108 was written in 1967, well before LEDs became available for the purpose of illumination, FMVSS-108 relied on the premise that the light source is a spherical emitter. The upper part of Figure 3 shows light from a spherical emitter delivering uniform energy to the eye.

As we can see in the lower half of Figure 3, light from an LED headlight has an intense peak energy in the center, and varying energy levels at different angles. The auto industry continues to use measurement techniques and software that was developed for spherical emitters, which means that that the results they get for LED headlights are invalid. NHTSA should create an entirely new standard for flat surface emitters; however, this has not happened yet.

Spatial, Spectral, and Temporal Properties

Light has many properties. The spatial property is the shape of the light. The spectral property is the energy at each wavelength. The temporal property is how the light is emitted in time.

Spatial Properties

The textbooks, standards, laws, regulations, formulas, and software were written for spherical emitters and assume uniform spatial energy. Light from a spherical emitter has the shape of a sphere, with the light source being the point at the center of the sphere, and each angle having the same energy. Light from a flat surface emitter has the shape of a bullet, with each angle having a different energy.

The descriptions and details of light from a flat surface emitter have not been taught to the engineers, legislators, the public, and the media, so there is currently a societal misunderstanding that LED light is just the same as regular light. This misunderstanding must be corrected through education, and standards must be updated to acknowledge the difference between light from spherical and flat surface emitters.

Spectral Properties

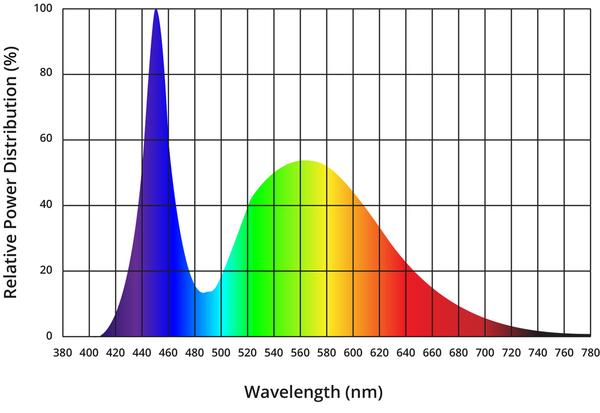

Human-visible light, whether it’s from a spherical or flat surface emitter, is generally composed of multiple wavelengths called the spectrum. The spectral output from an LED is different from a candle or an incandescent light bulb because a typical high-powered LED is mostly blue wavelength light, which just so happens to be the same wavelength that controls circadian rhythms, causes glare, and damages the eye.

Figure 4 shows the relative Spectral Power Distribution from a so-called 5500 Kelvin LED. The relative distribution does not tell us the absolute energy of the blue wavelength light, but it does show us that the blue wavelength light at 450 nanometers has the most energy. This blue wavelength also happens to be the most damaging for the human eye and causes the most glare. Blue wavelength light also suppresses the hormone melatonin, reducing the ability of cells to repair themselves at night.

Temporal Properties

With an emitter such as a candle or incandescent light bulb, the light is emitted continuously through time. This is not true for a flat surface LED emitter. First, an LED chip has an inherent flutter because of the way the photons are generated inside the chip. Second, an LED requires electronics to power the LED and an LED requires direct current. If the source of the electricity is alternating current, then diodes must be used to convert the A/C to D/C, which causes the electricity to then be pulsed, rather than continuous. This causes flicker which may be consciously noticeable, or subconsciously noticed. Engineers may also use Pulse Width Modulation to dim the light and this also causes flicker.

In addition to flutter and flicker, the lighting designer may choose to purposely turn the light on and off to create a flashing light. LED light turns on and off nearly instantly, rather than having a rise and decay time such as with an incandescent light. This type of flashing can be intolerable for humans because the brain cannot adapt quickly enough to the changing light energies.

Luminance

One of the key properties that standards bodies and government agencies have failed to address is that, because LED light is emitted from a flat surface, one of the key properties of light that must be measured is the flat surface density which is called luminance. Luminance can either be from light reflected from a flat surface, such as a piece of paper reflecting sunlight, or light can be emitted from a flat surface, such as from an LED. Luminance is measured in candela per square meter. Now that humans have invented the flat surface LED emitter, the textbooks, standards, and regulations should have been updated to make it clear that there are now two luminance sources: the emitted light from the LED chip, and the reflected light from the object surface.

The luminance across the surface of the LED chip is uniform. Within the electronic display industry, the luminance metric is well known. An LED computer monitor may have a light density of 300 candela per square meter (called ‘nits’ in the display industry). An electronic billboard may be 1,000 nits. At some level, the light is so dense, there will be damage to the eye. Eye damage is cumulative, so the more often the eye is damaged, the more total damage is done. Maximum human tolerance is about 50,000 nits.

For any flat surface, whether its an LED emitter or the reflected light from the roadway, the resulting spatial distribution is a mathematical Lambertian shape. This is measured as luminous intensity in candela. Because the light is spatially non-uniform, there is a peak luminous intensity, which will be directly in front of the middle of the chip. A major difference between the LED emitter and reflected light is the luminance. The typical values for luminance are somewhere around 0.1 to 10 candela per square meter, whereas the typical values for today’s LEDs are anywhere from 300 cd/m2 to 70,000,000 cd/m2. It’s this astronomical difference in intensity between what our nervous system has evolved for and what is now being subjected to from LEDs that make LEDs so hazardous.

Standards such as IES RP-8-18 for roadway lighting, and FMVSS-108 for car headlights do not contain the necessary metrics for LED light devices because they don’t address the issue of luminance. A valid standard would specify maximums for luminance to protect the eye and for neurological safety. Measurement of luminance must be done in a laboratory with precision instruments and the measurement must be taken in near field, less than 1 micrometer away from the chip. There is also a possibility that a digital camera can be used along with appropriate software to capture a reasonably accurate value for the luminance at a human-scale distance from the source.

While human comfort level for the density of visible light is approximately 300 nits, LED chip makers have already approached 100,000,000 nits5 of luminance, resulting in high risk of short-term and long-term eye damage, with babies and children being particularly at risk. In addition, due to the small 1mm x 1mm size of an LED chip, and due to the extreme density of the light, much of the energy emitted by the chip lands on the eye nearly invariant of distance. The bullet-shaped non-uniform energy profile interferes with normal human nerve functioning, causing seizures, migraines, panic attacks, anxiety, and agitation. The US Food and Drug Administration is the agency with sole authority to regulate LED products, but the FDA has not published any comfort, health, or safety regulations to protect people from this dangerous LED light.

What Needs to be Done?

The famed scientist Galileo Galilei was convicted of heresy2 for publicizing his evidence that the earth orbits the sun. 400 years later, we have a similar situation with the evidence1 that the shape of light emitted form a flat surface is not spherical. Standards bodies such as the Illuminating Engineering Society and Underwriters Laboratories claim3 that flat surface emitters are “point sources” of light. This claim has been proven false, yet this myth is perpetrated by those in power.

The solution to debunking the myth is education and legislative action. The encyclopedias and the textbooks must be updated to explain the difference between light from a spherical emitter and light from a flat surface emitter. The standards such as IES RP-8-18 and NHTSA FMVSS-108 must be updated to have separate sections for spherical and flat surface emitters.

Government officials at all levels, engineers, the media, and the public must all learn the difference between a spherical and flat surface light emitter and how the light from an LED causes adverse health effects. Government regulations must be redone and laws must be passed in accordance with this knowledge.

Footnotes

2: Galileo Galilei convicted of heresy

3: The Illuminating Engineering Society falsely claims that LEDs are “point sources”.

4: Underwriters Laboratories falsely claims that LEDs are point sources. “and with very small point sources, such as LEDs,”

5: LED peak luminance was approaching 100,000,000 nits in 2018 – Non-laser Light Sources: High-luminance LEDs target emerging automotive lighting applications

References for Point Source and Surface Source

1) https://sites.ecse.rpi.edu/~schubert/Light-Emitting-Diodes-dot-org/Sample-Chapter.pdf

2) https://ocw.snu.ac.kr/sites/default/files/NOTE/791.pdf

3) Surface Source: https://www.evergy.com/ways-to-save/resources-link/equipment/led-flood-and-area-lighting